Is Hiring a Manufacturing Consultant Worth it? [ROI Calculator Inside]

In today's fast-paced manufacturing landscape, businesses face a myriad of challenges, from optimizing production processes to navigating complex supply chains. Many manufacturing owners grapple with the decision of whether to enlist the help of a consultant to address these issues. We'll explore the value of hiring a manufacturing consultant and delve into key factors to consider before making this important decision.

How to Manage a Manufacturing Business?

Managing a manufacturing business entails overseeing various aspects, including production, supply chain management, quality control, and resource allocation. As the manufacturing landscape evolves, business owners face increasing pressure to streamline operations and maximize efficiency.

Key elements to consider are:

- Production Planning and Scheduling: Demanding forecasts, inventory levels, and resource availability.

- Supply Chain Management: Maintaining strong relationships with suppliers and manage inventory levels to avoid stock outs or excess inventory.

- Quality Control: Conducting regular inspections and invest in quality assurance systems.

- Technology Integration: Embracing technology to enhance manufacturing processes, improve efficiency, and gain a competitive edge. Explore the adoption of advanced manufacturing technologies such as robotics, IoT, and data analytics.

By effectively managing these aspects of a manufacturing business, owners and managers can optimize operations, drive growth, and maintain a competitive edge in the industry. So where does a manufacturing consultant come into play?

What does a Manufacturing Consultant Do?

A manufacturing consultant assists companies in improving their production processes, optimizing resource allocation and and achieving strategic objectives. First and foremost, manufacturing consultants analyze the existing processes within a company. They conduct thorough assessments to identify areas of inefficiency, bottlenecks, waste, and opportunities for improvement.

A manufacturing consultant’s role includes but is not limited to:

- Conducting Audits/Assessment: A manufacturing consultant begins by thoroughly assessing all aspects of a manufacturing business, including processes, systems, workflows, and personnel. At Twenty Helping Hands, we offer a complimentary no-commitment audit to help get you started.

- Process Optimization: By identifying improvement areas, the consultant works closely with the management team to optimize manufacturing processes, streamline workflows, eliminate bottlenecks, and reduce waste.

- Implementing Lean Principles: Lean manufacturing principles are often employed to streamline operations, minimize waste, and maximize value. As a matter of fact, Twenty Helping Hand’s lean methodology targets a 10x return without new machinery or hiring more staff.

- Engage the Team via Training and Development: Providing training and development programs for employees to enhance their skills, knowledge, and understanding of best practices in manufacturing.

- Strategic Planning and Decision-Making: Assisting in strategic planning and decision-making processes to ensure alignment with overall business objectives and long-term goals.

- Continuous Improvement: Fostering a culture of continuous improvement where employees are encouraged to identify inefficiencies and propose solutions. Implementing lean manufacturing principles and engage in regular training and development programs.

Analyzing Manufacturing Consulting Rates: The Investment vs. Return

One of the primary considerations for manufacturing owners is the cost of hiring a consultant. Manufacturing consulting rates can vary widely depending on the scope of services, expertise offered, and the consultant's reputation.

While fees vary depending on factors such as the consultant's experience, the complexity of the project, and the geographic location, below is a table outlining the average manufacturing consulting rates in the United States:

Looking to explore a project-package rate? You can book a no-commitment audit with our Lean Manufacturing Consultant at Twenty Helping Hands.

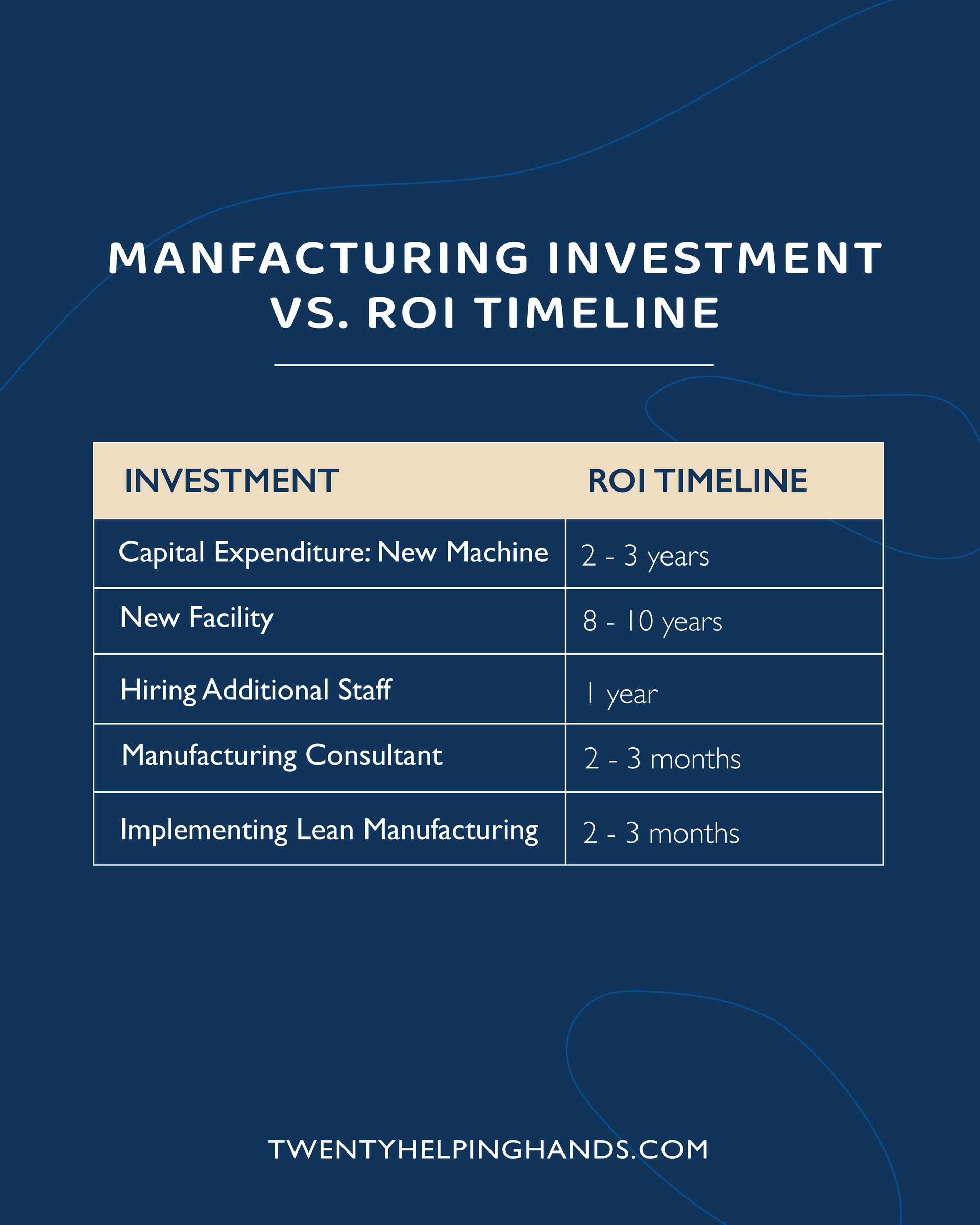

How do other investments measure against hiring a consultant?

Below is a table that explores the rate of return vs. time frame of anticipated return:

Understanding the Landscape: Engineering Consulting vs. Management Consulting

Engineering consulting and management consulting are two distinct fields that offer specialized services to businesses, each focusing on different aspects of operations and strategy. Here's a brief comparison:

- Engineering Consulting: Engineering consulting primarily focuses on technical aspects related to engineering, design, and project management. It involves providing expertise in areas such as structural engineering, civil engineering, electrical engineering, mechanical engineering, and other technical disciplines.

- Management Consulting: Management consulting, on the other hand, focuses on business strategy, organizational development, operational efficiency, and management practices. It involves providing expertise in areas such as strategic planning, process optimization, change management, and performance improvement.

Conclusion

In conclusion, hiring a manufacturing consultant can be a strategic investment for businesses looking to optimize operations, drive growth, and stay competitive in today's dynamic marketplace. By leveraging the expertise of a consultant and embracing a culture of continuous improvement, businesses can unlock new opportunities for success.

Finding a Lean Manufacturing Consultant in Chicago

If you're in the Windy City, finding a local expert is as easy as ordering deep-dish pizza. Working with a Lean Manufacturing Consultant in Chicago means you have someone who understands your local business landscape, just like a tour guide showing you the best spots in the city.